This whole project originated from finding a solid chunk of melamine coated MDF that came from a university desk. The legs on it broke and our facilities management was throwing it out. I made some new legs out of 75mm square tube with 5mm wall. The finished table weighs 60kg and feels like it "could hold an elephant". I tried something unique with the tripod design.

It works well as it never wobbles, but you can't sit on the edge of the table on the one leg side. The whole table comes apart and packs flat so I can easily move, store and transport it.

Saturday, June 9, 2018

One Day Build: Strong Indicator Arm

For a while now I have been using one of these ubiquitous Swiss made indicator arms. It works okay but I've never been fully happy with it. They have too many joints and too much wiggle for precision work. Even on the best units I have seen problems with the indicator alignment when indicating small holes. The dovetail isn't perfectly radial with the stem and it side loads the contact point.

I wanted a better, simpler solution. I came up with this single pivot arm inspired by some cheap indicator arms I've seen. The clamp plates are hardened A2 and the shank is 60 case Thomson rod. The spherical surface on the clamp plates were surfaced on a CNC and match the spherical indents on the shank.

The screw is kinda cool. Its a standard SCHS with a little plastic knurled knob pressed on. I didn't know these existed until one of the toolmakers I work with bought some a job. The clamp gives just enough friction on the joint that it wont be knocked out of place, but can easily be adjusted by hand.

The little spring on the front of the clamp is just there to hold the clamp plates on the shank and the dovetail open when the indicator is not on the arm. Right from the start the radial alignment wasn't perfect. This this design, that alignment is easily adjusted by grinding the faces of the clamp plates to affect the angle the indicator is held at. With a bit of fiddling I got the contact tip to less than 0.25mm radial misalignment.

This isn't a perfect solution for every application but it works perfect for any time you need an indicator in a mill spindle. Going forward I would make a second one of these with a 10mm reduced shank for using in my small drill chuck.

|

| Example of the suspect indicator arm. Photo from wttool.com |

Wednesday, May 9, 2018

Adjustable Prismatic Square

This small square was my first ever toolmaking project. I wanted a small square to use when squaring blocks in the mill. There wasn't material available to make a one piece square, and I'm still unsure about how silver soldered machinists squares are ground on all sides after assembly. So, the base and blade would have to be two pieces, and why not make them adjustable. I didn't go for a traditional rectangular blade like often seen in combination squares because grinding such a thin part would be very challenging, and grinding the mating slot nearly impossible.

Instead I used a square profile blade clamped at 45 degrees. This allows for easy clamping with the clamp remaining withing the edges of the base. The clamp is spring loaded so it loosens easily. The blade is made from a M2 HSS tool bit and the base is 1095. Its a fun little quirky square. I didn't do any formal design for this; no sketches even. As a result the proportions are a little clumsy but that doesn't effect its use.

|

| Close up of clamp with blade in a middle position |

|

| Small relief for checking an outside corner |

Tuesday, May 8, 2018

Stainless Steel Clean Room Pressure Vessel

This was a job for our micro-electronics manufacturing clean room on campus from about two years ago. The previous tank was made of 1.5mm 304 stainless and would balloon out with applied pressure. The clean room tech designed a new tank made with 6mm walls and asked us to build it. All the parts were cut on a water jet with a few machined fittings. The main labor in the project was all the welding.

Every seam was TIG welded inside and out. I first welded the bulkhead rim on to the front panel inside and out. This significantly bowed the plate, so I had to flatten in on a hydraulic press. From there it was standard fillet and butt welds, with many in the confines of the tank. The only seams not welded inside and out were the ones joining the final back plate to the main body of the tank. The bulkhead opening in the front was just too small to reach in and weld. The designer had thought of this and had made the back plate slightly larger to allow for a double pass of weld to attach it. After all the parts and ports were welded, the sealing surface of the bulkhead was milled to ensure flatness.

This was a really fun project because it challenged me to do more non-dominant hand welding. I was reasonably proficient using my non-dominant foot to control my pedal, but only had limited experience with welding left handed. In total I laid over 7m of weld, at least 2 of which was left handed.

One Day Build: Gale Crater Topographic Model

I decided to carve a small model of Gale Crater, the current location of the Mars Science Laboratory. The model from NASA had a 3x vertical exaggeration, which I reduced to 2x. Made out of a scrap of PVC, the model is around 200x150 mm. It ran on a machining center overnight and took an estimated 16 hours. It was supposed to run faster, but motors on this machine are very low torque, so the feed rate is dynamically throttled to ensure the axes won't overshoot. All mesh editing and programming I did in Fusion360 and it ran on a Trak 2 Op.

|

| As a result of mesh reducing, the model has a beautiful, faceted effect |

Monday, April 30, 2018

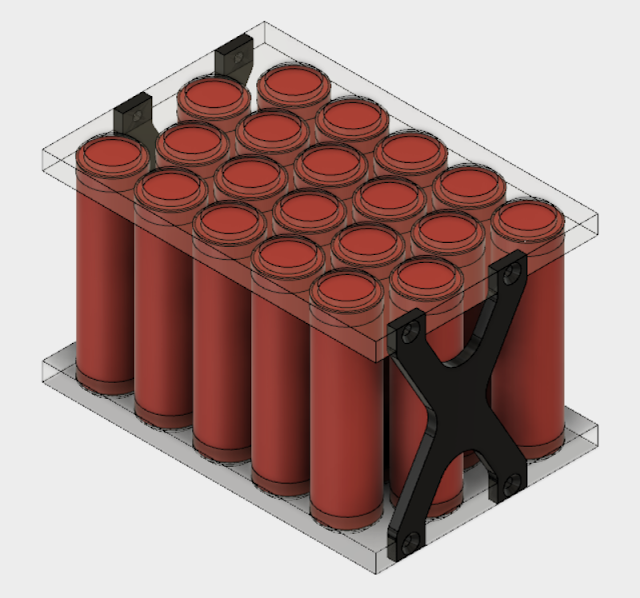

Modular 18650 Battery V3

This is another post in the series about designing an electric moped. This post mainly details the system architecture and high level design. I avoid delving into the calculations I used. This post also doesn't cover BMS design and programming. This may be detailed in a future post.

For designing the battery I focused on the maximum power draw required. For my intended use - running around town while at school - I'm not particularly focused on range. While I aim for a 100km range, I don't have enough information about my preliminary designs to know if this is possible. I began by calculating maximum power required. The motor will draw maximum power when accelerating so I decided on required power from my desired acceleration.

The calculations are kept simple, and ignored air resistance; I have calculated air resistance but it wasn't significant enough, especially during acceleration to warrant factoring it into the calculations. For my vehicle target weight, and wheel size, I decided I need to be able to supply a sustained 5kw. To avoid needing an impractical amount of current, I aimed to keep the volts to amps ratio at 1:1. Because the micro controller I want to use has only 16 analog inputs, this means I can monitor at most 16 cells in series. Working this in to my target voltage/current ratio of 1:1, I settled on a battery topology of 16s20p. This gives a maximum power output 6.4kw at 5 Amps/cell, and a nominal power output of 2.9kw at 2.5 Amps/cell.

But enough of murky math, on to the design details. I decided I wanted a modular batter for several reasons. First was cost; I could start with fewer modulus and in case this whole thing didn't work out or I couldn't make it safe enough, I wouldn't be out a lot of cash in cells. If it did work, I could add more modulus later. Second was charging. Interfacing with a type 2 EV charger isn't particularly difficult, but it provides 240 volts, and the power supplies I would need to charge the battery would cost a lot, weigh a lot, and take up a lot of space. Charging on 120 volts wouldn't really make it any better as a high voltage and current would still be required.

The modular battery system allows modulus to be removed individually for charging. Its a novel idea and isn't practical for larger, or production vehicles. For a small moped, its a cool idea. I really like the physicality of removing modulus to charge them; it gives you a close connection to the bike. The BMS would signal to the rider what modulus need to be removed for charging. When a socket is not in use, it could be bridged with a jumper. The BMS could easily recognize the jumper and make appropriate adjustments.

The first sketches of the modular battery packs used a pivoting arrangement, with the loose end being held in by a rubber draw latch. This proved too complex for connectors between the pack and bike, as well as for waterproofing the modulus and the connections. The second idea was to use racks the modulus would slide into. The racks would be inside a waterproof enclosure with only 2 doors. This simplified connections and solved the waterproofing problem. This also made cooling much easier as forced air cooling in the battery box could now be used.

My first iteration of this design used mostly machine parts screwed together. I wanted all the module frames to be insulating and fire retardant if possible. End plates machine of polycarbonate spaced out by water jetted G10 spacers. This design was going to be expensive for fasteners, materials, and time. It also had stiffness issues, and would most likely suffer from cracking around the screws. After playing with it for a bit, I let it rest for a few months while I reevaluated.

I don't remember where the idea came from, but I wanted to try the rack mount modules with 3D printed frames. I don't generally like hobby level 3D printing. Its probably from years of working with students who ask for help with poorly designed, printed parts trying to implement poorly thought out ideas. Note to the reader; drilling and tapping a 30% infilled part never works, no matter how many student groups try it. I wanted to try it anyway, what could go wrong. My first 3D printed design I stopped only halfway though; I really wasn't happy with it. I was still in the mindset of machining and weight saving; trying to make the parts and thin and light as possible.

You can probably see why I stopped. All the thin walls and tabs were too liable to snap off. It also would require a lot of support structure underneath due to a rim running around the underside. The model tree structure was also a mess and I had new ideas on how to structure it. I still didn't feel good about how I was designing it. Taking a pause, I thought about what I really was trying to do, not how I was going to do it. I started a new model with the goal of creating models as if these were going to be mass produced. What materials and techniques would be used then?

Some basic facts: it would be injection molded, it would most likely be out of glass filled nylon, it would most likely have torsional stiffness issues. These were the bases I needed. Attacking it again I got version 3.

I am very pleased with how version 3 came out, even though I already have improvements in my head. All the cells are parallel with each other, with spaces between for air flow. The contacts of the cells are soldered to copper bus bars under the front and rear covers. Both of these bus bars terminate in the tab on the front right of the module, where they attach to insulated copper pins that plug into sockets on the rack mounts. The tab is offset to allow two modules to oppose each other and use a central set of sockets.

The connection pins are surrounded by a plastic tube to prevent accidental shorting. As these modulus are going to be removed regularly, its very important the modules are safe. The sockets on the rack mount have a unique shape. They allow for modules to be connected in series with appropriate polarity and allow the same packs to be used on either side of the sockets. I will most likely have a post in future with details and models of the sockets and rack mount. This central set of sockets would also have LEDs, one for each module to show the rider which modules have the lowest voltage and need to be charged next. The central sockets will also have spring contacts to connect to the module for temperature monitoring.

I at first planned to use RTDs of some kind, but this would require additional analog inputs on the micro controller. Thinking about how I would process these inputs, I realized all I would be doing is monitoring them in reference to a threshold value. I don't need a micro controllers for this, I can just use digital thermal switches wired to digital inputs. Only two contact are needed for multiple switches to be wired in parallel. If any run over temperature, the circuit will close causing a system shutdown.

The front and rear frames are deeply ribbed to improve their area moment of inertial to reduce deformation. I also tried to make the connecting surfaces between the two frames as large as possible to increase stiffness. The two halves are held together with 6 screws specific for plastic. The square grooves on the outside edges are for the rack mounts. 6mm rails will be on the racks and the modules will slide into them. The filled in sections near the corners on the rear frame in the photo below is to allow for a place for the cover plate screws to attach. I also predict the corners will get abused a lot, so I made their walls thicker.

The copper bus bars are distinct to each side. To run power from the rear from to the front frame where the connectors are, a thin piece of copper runs up the bottom of a rail groove. This is fairly well sheltered so I am not worried about shorting. I also plan to cover this run with a thick piece of Kapton tape just to be safe. The batteries will be soldered to the copper bus bars with small jumper wires. The jumpers will be sized with a fusing current around 5-6 amps. This is a safety measure in case any cell is over current. The wire will melt and disconnect the cell. This is similar to how Tesla builds their batteries. The bus bars will just be held in place with some hot glue or CA glue. On the front frame the two bus bars get pretty close to one another. There is a least a 5mm air gap. I'm not worried about this because the bus bars wont move, and there is at most a 4 volt differential between these bus bars. There is very little chance of anything happening.

The front and back covers serve just to cover the bus bars and are held on with smaller versions of the designed for plastic screws. Fasteners will cost a lot for these modules. I already know how I'm going to eliminate 4 from the next design iteration, but I refuse to save money by buying phillips or slotted head screws. I won't do it. All in all the pack is very light, weighing in at 1.47kg, with only 80g of that being the plastic frames and copper bus bars.

Like I mentioned I already have ideas to make this design more reliable, use fewer screws, and have easier to assemble bus bars. I also need to incorporate a handle somewhere to allow easy removal from a slot in the rack. I also worry the tab holding the high current pins will break, but talking to manager of our maker space, he assured me there is little worry of it breaking. The next design will include the basic structure of the central sockets as well as the battery packs.

For designing the battery I focused on the maximum power draw required. For my intended use - running around town while at school - I'm not particularly focused on range. While I aim for a 100km range, I don't have enough information about my preliminary designs to know if this is possible. I began by calculating maximum power required. The motor will draw maximum power when accelerating so I decided on required power from my desired acceleration.

The calculations are kept simple, and ignored air resistance; I have calculated air resistance but it wasn't significant enough, especially during acceleration to warrant factoring it into the calculations. For my vehicle target weight, and wheel size, I decided I need to be able to supply a sustained 5kw. To avoid needing an impractical amount of current, I aimed to keep the volts to amps ratio at 1:1. Because the micro controller I want to use has only 16 analog inputs, this means I can monitor at most 16 cells in series. Working this in to my target voltage/current ratio of 1:1, I settled on a battery topology of 16s20p. This gives a maximum power output 6.4kw at 5 Amps/cell, and a nominal power output of 2.9kw at 2.5 Amps/cell.

But enough of murky math, on to the design details. I decided I wanted a modular batter for several reasons. First was cost; I could start with fewer modulus and in case this whole thing didn't work out or I couldn't make it safe enough, I wouldn't be out a lot of cash in cells. If it did work, I could add more modulus later. Second was charging. Interfacing with a type 2 EV charger isn't particularly difficult, but it provides 240 volts, and the power supplies I would need to charge the battery would cost a lot, weigh a lot, and take up a lot of space. Charging on 120 volts wouldn't really make it any better as a high voltage and current would still be required.

The modular battery system allows modulus to be removed individually for charging. Its a novel idea and isn't practical for larger, or production vehicles. For a small moped, its a cool idea. I really like the physicality of removing modulus to charge them; it gives you a close connection to the bike. The BMS would signal to the rider what modulus need to be removed for charging. When a socket is not in use, it could be bridged with a jumper. The BMS could easily recognize the jumper and make appropriate adjustments.

The first sketches of the modular battery packs used a pivoting arrangement, with the loose end being held in by a rubber draw latch. This proved too complex for connectors between the pack and bike, as well as for waterproofing the modulus and the connections. The second idea was to use racks the modulus would slide into. The racks would be inside a waterproof enclosure with only 2 doors. This simplified connections and solved the waterproofing problem. This also made cooling much easier as forced air cooling in the battery box could now be used.

My first iteration of this design used mostly machine parts screwed together. I wanted all the module frames to be insulating and fire retardant if possible. End plates machine of polycarbonate spaced out by water jetted G10 spacers. This design was going to be expensive for fasteners, materials, and time. It also had stiffness issues, and would most likely suffer from cracking around the screws. After playing with it for a bit, I let it rest for a few months while I reevaluated.

|

| First machined version of the rack mount modules |

|

| First 3D printed version of rack mount modules |

Some basic facts: it would be injection molded, it would most likely be out of glass filled nylon, it would most likely have torsional stiffness issues. These were the bases I needed. Attacking it again I got version 3.

|

| Second 3D printed version of rack mount modules |

|

| Half the battery pack. Note how all the tabs nest together. |

|

| All of these modules are connected in series |

|

| Layout of sockets on the rack mount |

I at first planned to use RTDs of some kind, but this would require additional analog inputs on the micro controller. Thinking about how I would process these inputs, I realized all I would be doing is monitoring them in reference to a threshold value. I don't need a micro controllers for this, I can just use digital thermal switches wired to digital inputs. Only two contact are needed for multiple switches to be wired in parallel. If any run over temperature, the circuit will close causing a system shutdown.

|

| The high current pins with their protection. The two small holes will receive press fit copper contact for thermal switches |

|

| Rear frame. Note deeply ribbed and crossed base section |

|

| Front and rear frames assembeled |

|

| Upper bus bar showing the termination points in the lower right on the tab |

|

| Detail showing rear bus bar running up the bottom of a rack mount groove |

Like I mentioned I already have ideas to make this design more reliable, use fewer screws, and have easier to assemble bus bars. I also need to incorporate a handle somewhere to allow easy removal from a slot in the rack. I also worry the tab holding the high current pins will break, but talking to manager of our maker space, he assured me there is little worry of it breaking. The next design will include the basic structure of the central sockets as well as the battery packs.

Saturday, April 28, 2018

One Day Build: Carbide Foot Depth Mic

When cleaning the shop where I work one day, I found an old Tesa micrometer head. It was very unique as the sleeve was graduated only in 0.1 inch increments, not the traditional 0.025 inch. The thousands indication was instead done with a set of rotation indicators behind a window that ticked off every 5 thousandth. The micrometer was also graduated in 0.0005 inch increments with a 0.0001 vernier. Its a very beautiful and high quality tool but it had be abused and left in disrepair; the locking screw was missing, it was quite dirty and gummed up. I took it into my care and after a disassembly, cleaning, adjustment and a homemade replacement part, it was good as new.

Now what do I do with it? I have a very accurate outside micrometer already. I decided a depth micrometer would be very useful, especially when grinding thin parts on the surface grinder. Even though this micrometer head is intended for outside use, you can still measure depth by subtracting the read measurement from 1. The issue with using it on the grinder is it will stick to the chuck. Simple solution; use carbide.

The body of the is foot hardened A2. It was all machined out of my head, no drawings or CAD. I tried brazing the carbide blocks in but we just don't have the right type of flux where I work and I ended up having to remake the steel part. As a substitute for brazing I glued the blocks on with Loctite 380. All sides were ground after the glue cured.

The micrometer head is held in with a split pipe thread bushing. With pipe threads being tapered, if you cut a slit in a male pipe fitting, the fitting will collapse as you tighten it. After grinding I very carefully trammed a milling machine and took a skim cut on my fixture plate. I clamped the foot down flat to the fixture plate to ensure the bore I put in the bushing was as close to square to the bottom face as possible. Under slight pre-tension, I bored the brass bushing to fit the micrometer head.

Assembly was straightforward after that. I set the micrometer head within .005 inch in the bushing, then used the sleeve to zero it. The tool has a very consistent repeat reading. I checked the accuracy with gauge blocks and the reading is spot on. The issue I did find was the foot has a .0006 inch convex bow in it. This changes the micrometer reading depending on which side of the foot you apply pressure to. I want to fix this in the future but I can only see doing this through lapping. I don't have any lapping equipment right now. However, under normal use the tool still is very usable, and most importantly doesn't stick to the mag chuck when grinding.

Now what do I do with it? I have a very accurate outside micrometer already. I decided a depth micrometer would be very useful, especially when grinding thin parts on the surface grinder. Even though this micrometer head is intended for outside use, you can still measure depth by subtracting the read measurement from 1. The issue with using it on the grinder is it will stick to the chuck. Simple solution; use carbide.

The body of the is foot hardened A2. It was all machined out of my head, no drawings or CAD. I tried brazing the carbide blocks in but we just don't have the right type of flux where I work and I ended up having to remake the steel part. As a substitute for brazing I glued the blocks on with Loctite 380. All sides were ground after the glue cured.

The micrometer head is held in with a split pipe thread bushing. With pipe threads being tapered, if you cut a slit in a male pipe fitting, the fitting will collapse as you tighten it. After grinding I very carefully trammed a milling machine and took a skim cut on my fixture plate. I clamped the foot down flat to the fixture plate to ensure the bore I put in the bushing was as close to square to the bottom face as possible. Under slight pre-tension, I bored the brass bushing to fit the micrometer head.

Assembly was straightforward after that. I set the micrometer head within .005 inch in the bushing, then used the sleeve to zero it. The tool has a very consistent repeat reading. I checked the accuracy with gauge blocks and the reading is spot on. The issue I did find was the foot has a .0006 inch convex bow in it. This changes the micrometer reading depending on which side of the foot you apply pressure to. I want to fix this in the future but I can only see doing this through lapping. I don't have any lapping equipment right now. However, under normal use the tool still is very usable, and most importantly doesn't stick to the mag chuck when grinding.

Transverse Flux Motor V6

This is part of a larger project I started in some free time over the last summer. I was on co-op with a company working on a hybrid system. Being exposed to the industry made me realize that what i thought was the gradual and eventual transition it hybrid and electric vehicles isn't happening as fast as I thought. I always had an interest in electric vehicles because of their emissions potentials and because they are quiet. I decided to get back into electric vehicles. My school has a few electric vehicles and hybrid electric teams. I have tried attending meetings with all of them and talking with team leadership about team vision and plans. While I believe the teams are doing some really cool work, I find myself incompatible with the team cultures and operation models.

I instead decided to design my own electric vehicle. Cars are cool but I already have a car, so I don't really need a second one. Cars are also very challenging to build them road legal, let alone finding someone to insure you. For a while I rode a 1982 Honda moped and loved it. Eventually I sold it when I moved and I've really missed it. In my area, you don't need a motorcycle license for a moped and they are required to be inspected. They are also much easier to be insured. So I started sketching and brainstorming for a small electric moped.

I want to design everything myself; battery, BMS, motor, motor controller, frame. This post focuses on the motor design I settled on and the first version of the model I developed. I began by reading research papers. There is a lot on forums about motor design but much of it lacks solid engineering fact behind it; research papers provided the detailed information. Traditional laminated core in-runner motors I decided were too complex to build, even though they were the most common. They require a lot of reliance on outside vendors to cut the laminations, and a ton of time winding the slots. I wanted something simple and easy.

Reading research papers about various motor designs, I found something called a transverse flux motor. Originally an in-runner motor, I decided an out-runner with a Halbach array would give the highest torque density. After playing around with 6 different sizes and configurations, I finished a small scale model of the motor described. This motor only has two phases as that is all that is required. It is designed much like out-runner motors found in model aircraft.

Each phase has only one large coil. Interlaced around it are small horseshoe shaped laminations. They alternate inside and outside the coil, causing a reversed polarity on each horseshoe. The two phases are offset by halve a phase so no offset would be required in the magnets in the rotor. The light grey annulus is the mounting surface for the motor. The horseshoe laminations key into this mounting structure and and spaced apart by plastic insulators. The two phases are held in place by a lock nut on the back of the mounting structure.

The rotor is made of a single tube of plastic, slotted internally to space out the permanent magnets. Its a very unconventional design and difficult to prototype, but it is the best way I could think of doing it without laminating it. On the rear end is a cap with the main bearing in it. This bearing seats on to the stator via the phase lock nut. A small aluminum ring is pressed into the opposing side of the rotor to prevent possible collapse or deformation of the plastic tube. This design really needs a second bearing for support at one end or the other.

I ultimately rejected this design because of the complexity of the rotor, and the wiring of the leads out of the phase. With how I wanted to build it, large or small, there was virtually no space to run the power leads from the rear most phase to the mounting flange. I eventually decided to move to an axial flux motor design. There are many documented cases of axial flux motors performing to very high standards while there are virtually none of transverse flux motors preforming at high levels.

My designs for axial flux motors will be featured in future posts.

I instead decided to design my own electric vehicle. Cars are cool but I already have a car, so I don't really need a second one. Cars are also very challenging to build them road legal, let alone finding someone to insure you. For a while I rode a 1982 Honda moped and loved it. Eventually I sold it when I moved and I've really missed it. In my area, you don't need a motorcycle license for a moped and they are required to be inspected. They are also much easier to be insured. So I started sketching and brainstorming for a small electric moped.

I want to design everything myself; battery, BMS, motor, motor controller, frame. This post focuses on the motor design I settled on and the first version of the model I developed. I began by reading research papers. There is a lot on forums about motor design but much of it lacks solid engineering fact behind it; research papers provided the detailed information. Traditional laminated core in-runner motors I decided were too complex to build, even though they were the most common. They require a lot of reliance on outside vendors to cut the laminations, and a ton of time winding the slots. I wanted something simple and easy.

Reading research papers about various motor designs, I found something called a transverse flux motor. Originally an in-runner motor, I decided an out-runner with a Halbach array would give the highest torque density. After playing around with 6 different sizes and configurations, I finished a small scale model of the motor described. This motor only has two phases as that is all that is required. It is designed much like out-runner motors found in model aircraft.

|

| Finished transverse flux motor |

|

| Finished transverse flux motor with rotor removed, only one phase is shown. |

|

| Cross section of the phase, blue lines show where the copper winding would be |

|

| Motor rotor, note the complex fin shapes in the plastic tube and the single, large bearing |

I ultimately rejected this design because of the complexity of the rotor, and the wiring of the leads out of the phase. With how I wanted to build it, large or small, there was virtually no space to run the power leads from the rear most phase to the mounting flange. I eventually decided to move to an axial flux motor design. There are many documented cases of axial flux motors performing to very high standards while there are virtually none of transverse flux motors preforming at high levels.

My designs for axial flux motors will be featured in future posts.

Thursday, April 26, 2018

A Sight Development

One of my longest running distinct design projects is an Olympic recurve style sight for target archery. Finally coming to fruition after more than three years of design and sketches, this post will outline some of the features and design process I went through building this sight. For those who don't know what a recurve archery sigh is, it is a small aperture that is adjustable in vertical and horizontal axis and is supported a distance from the bow.

I have been doing archery for nearly 10 years now and have been using my same equipment seven of them. This project spawned out of discontentment in my current sight. Being a capable engineer, I couldn't justify the price of a high quality production sight, so I toyed with the idea of building one. There were a few distinct features I wanted that could be found in commercially available products, as well as many of my own ideas that I hadn't seen implemented anywhere and I wanted to try.

The final design has detented screws on both axis for easy adjustment. This is common on most high end sights, with the difference being my design uses a smaller and finer pitch screw for vertical adjustment to reduce weight. Most sights use a larger screw to handle the side loading from having a nut that contacts the screw from only one side. I incorporated a half nut backer to eliminate any side loading on the screw.

The horizontal adjustment went through perhaps the most design revisions of any element on the sight. My original sketches were based on current designs and used ground guide pins and a lead screw for adjustment. I tried for a long time to find an arrangement of pins and screw that would be very compact and light weight. After sketching on and off for 2 years, I took a break. When I came back, I saw all my old designs as overbuilt and would be better suited to industrial machinery or machines tools; far more than is needed for a sight.

My next idea was to use a parallel flexible for the axis. While simple, it proved to be too large for my self imposed size restrictions and never made it beyond sketches. I started looking closer at my current sight and decided I could use the simple (and hard to adjust) mechanism from my current sight and adapt it to have larger control features and not require any locking screws.

This design uses a nut with a fit similar to that of a nyloc nut, threaded directly on to aperture's thread. By using the thread on the aperture, the weight and size of the mechanism is greatly reduced. With the flat on the nut resting against the cover plate, it cant rotate but will slide freely. Coarse adjustments can then be made by rotating the end of the aperture in 180 degree increments. Fine adjustments are made with the large knob which is detented into the body of the sight, and threaded onto the aperture. The whole system is preloaded with an internal spring.

One of my other requirements was for the sight to collapse flat for storage. Most sights achieve this by having the aperture removable. My original idea was to have the entire aperture fold flat to the main frame, eliminating the chance of dropping small parts in the grass when shooting outside. This mechanism proved to be too large in my various designs so I opted for a removable aperture. With the new horizontal adjustment, the aperture alone could no longer be removable. Instead I made the whole horizontal adjustment mechanism removable.

The removable element is indexed with two perpendicular planes, restricting two transnational and three rotational axis of movement. The final transnational axis is indexed with a flat head thumb screw (not seen above). The thumb screw is captive so it wont get lost.

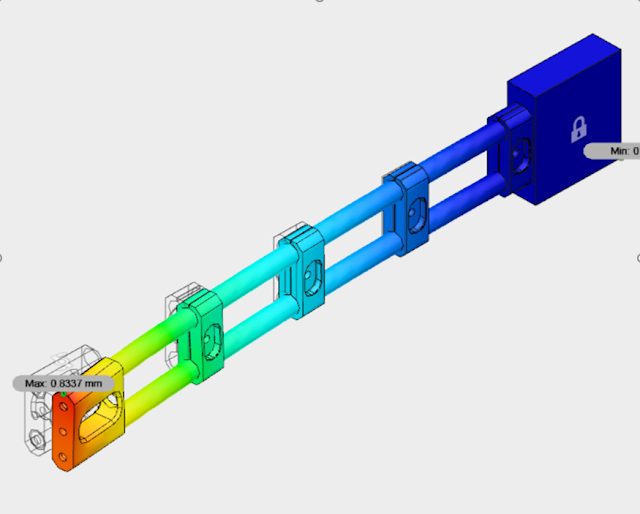

The sight extension is made from two thin wall unidirectional carbon fiber tube. When you shoot archery outdoors, you loose arrows. When you are looking for your arrows, you find other lost arrows. As such I have a collection of old, often broken arrows I've found over the years. I like saving useful and expensive things and these tube qualify. I wanted to reuse some of these tubes for the extension because they are very light, stiff, straight, and consistent in diameter. I am convinced the 2 tubes will be strong enough to resist and bending moment, but I have reservations twisting them about their axis. If I build this sight and I find the extension is not torsionally rigid enough, I will add simple spacing braces between the two tubes at intervals down their length.

As you twist a 2 tube system like this, the midpoints of the tube tend to bend closer to each other. If you brace these apart, you are then transforming the torsional and bending forces on the individual tubes to tension forces, which tubes are much stiffer in. This would be a vary simple addition to make if needed.

Designing and modeling this project was a lot a fun and the culmination of more than 3 years of ideas and sketches, consulting with engineers, archery professionals and amateurs. I'm currently in the middle of building this sight with about 50% of components complete (by number). By amount of work, I would say its more like 70% complete. I worked from the most complex components - bed, saddle, carrier, split nut - first. If any of these components didn't work out as intended, I wouldn't have wasted time on a lot of the simpler components.

I have been doing archery for nearly 10 years now and have been using my same equipment seven of them. This project spawned out of discontentment in my current sight. Being a capable engineer, I couldn't justify the price of a high quality production sight, so I toyed with the idea of building one. There were a few distinct features I wanted that could be found in commercially available products, as well as many of my own ideas that I hadn't seen implemented anywhere and I wanted to try.

|

| The final design |

The horizontal adjustment went through perhaps the most design revisions of any element on the sight. My original sketches were based on current designs and used ground guide pins and a lead screw for adjustment. I tried for a long time to find an arrangement of pins and screw that would be very compact and light weight. After sketching on and off for 2 years, I took a break. When I came back, I saw all my old designs as overbuilt and would be better suited to industrial machinery or machines tools; far more than is needed for a sight.

My next idea was to use a parallel flexible for the axis. While simple, it proved to be too large for my self imposed size restrictions and never made it beyond sketches. I started looking closer at my current sight and decided I could use the simple (and hard to adjust) mechanism from my current sight and adapt it to have larger control features and not require any locking screws.

|

| The simple adjustment mechanism. Note: a spring is not visible in the model. |

One of my other requirements was for the sight to collapse flat for storage. Most sights achieve this by having the aperture removable. My original idea was to have the entire aperture fold flat to the main frame, eliminating the chance of dropping small parts in the grass when shooting outside. This mechanism proved to be too large in my various designs so I opted for a removable aperture. With the new horizontal adjustment, the aperture alone could no longer be removable. Instead I made the whole horizontal adjustment mechanism removable.

The removable element is indexed with two perpendicular planes, restricting two transnational and three rotational axis of movement. The final transnational axis is indexed with a flat head thumb screw (not seen above). The thumb screw is captive so it wont get lost.

The sight extension is made from two thin wall unidirectional carbon fiber tube. When you shoot archery outdoors, you loose arrows. When you are looking for your arrows, you find other lost arrows. As such I have a collection of old, often broken arrows I've found over the years. I like saving useful and expensive things and these tube qualify. I wanted to reuse some of these tubes for the extension because they are very light, stiff, straight, and consistent in diameter. I am convinced the 2 tubes will be strong enough to resist and bending moment, but I have reservations twisting them about their axis. If I build this sight and I find the extension is not torsionally rigid enough, I will add simple spacing braces between the two tubes at intervals down their length.

|

| FEA of side loading of the extension with spreader brackets measuring for deflection |

As you twist a 2 tube system like this, the midpoints of the tube tend to bend closer to each other. If you brace these apart, you are then transforming the torsional and bending forces on the individual tubes to tension forces, which tubes are much stiffer in. This would be a vary simple addition to make if needed.

Designing and modeling this project was a lot a fun and the culmination of more than 3 years of ideas and sketches, consulting with engineers, archery professionals and amateurs. I'm currently in the middle of building this sight with about 50% of components complete (by number). By amount of work, I would say its more like 70% complete. I worked from the most complex components - bed, saddle, carrier, split nut - first. If any of these components didn't work out as intended, I wouldn't have wasted time on a lot of the simpler components.

Labels:

Archery,

CAD,

CAM,

FEA,

Fusion360,

homemade tool,

toolmaking

Uncommon Press

Like some of my previous posts, this project was another senior project at my university. The team was tasked with designing and building a recreation of a 18th century wooden printing press. Most of the wood and iron parts were done at a local living museum. Only the most critical metal components were done in our shop. At the core of this press is a screw that generates the pressing force as you pull on the handle. When these presses were built in the 18th century, screw cutting lathes were not a thing, and as such the screw would have been made using a mix of files, saws and chisels. While the team wanted as faithful a recreation of a press as possible, we drew the line at trying to file threads by hand. The mating brass nut would have been cast in place around the finished screw (similar to babbit bearings), and the team originally wanted to do this.

At first this didn't pose a huge issue. While the central screw was exotic, we didn't think it was impossible. The thread is a 2 and 5/16 inch major diameter, 3/16 square thread form, 3 start, 2 inch lead. The most unique part was the very large lead. Originally one of the full time machinists intended to do this thread on our larger ProtoTrak lathe, but we quickly found out between minimum spindle speed and maximum carriage federate, it would be impossible. At this point everyone else in the shop dusted their hands and backed away from the part. I was the only one who was willing to give it a shot it one of our newer machines.

We had just received delivery of a demo machine, a Tsugami dual spindle y-axis lathe. I ended up coding everything for both the thread and the nut by hand. The external thread was very straightforward to program, but the threading tool gave me a lot of trouble. The idea was to use inserted acme threading tools reground for a square profile but the tools kept cracking off due to how much relief for the large thread lead. After some trial and error (and snapping 12mm cobalt tool blanks in half on the machine during testing) i found a tool geometry that worked. I ran the external thread for both the final part, as well as a shorter, lighter version for me to use as a thread gauge.

Lucky for me all of these parts were bespoke, so I only had to make one of each nut and thread and they only had to fit each other. With the external thread complete, I moved on to the internal thread. To this day the brass stock for this nut was the most expensive piece of material I have worked with; 600USD (with half of the cost being in overnight shipping). Unlike the external thread where I could cut the entire thread form with a single tool, the internal thread would require a tool 1/2 inch wide, which would cause chatter no matter how rigid the lathe is. I decided make each internal grove with 5 separate passes with a thin tool on the end of a boring bar. The tool was a smaller version of the external threading tool bolted into the end of a large and stubby boring bar that I also made.

Again, I manually wrote the program for the internal threads, mostly because I had no idea how I would achieve my desired approach in CAM. This meant for making one set of internal threads, there was 15 independent threading cycles that had to run. Now, because I decided to tweak the nut to fit the screw, I would have to change each of those 15 threading cycles to change the fit. To eliminate this, I parameterized the code. The z thread length and major diameter are both driven by variables at the beginning of the program, so I could easily tweak the program at the machine by changing a single value; not 15 values. I chose to parameterize the z thread length because as I was testing the program, I didn't want to use a ton of material.

The strange thread wasn't the only odd feature on the screw. It also included a tapered, rectangular hole. We dont have and EDM capacity at our shop and the team didn't have money to have it sent out. Again, I stepped up the challenge and said I would do it. I pre-drilled to remove most of the material before welding our main band saw's blade into the hole. I first squared out the hole with the band saw, before angling the saw table and band filing a 1 degree taper on all walls. The fact that this technique left a rough finish on the walls was beneficial to the design team, who didn't want perfect faces and surface finishes. On many of the pieces we went back with files and sand paper to roughen up the parts to make them look more handmade.

The job was a lot of fun overall and the printing press is now on display at my university. I grew to like that Tsugami lathe but sadly its been moved out to be replaced with some other machines. I also did some miscellaneous parts and welding for the press, one part can be seen below.

A 5 part series of articles about the building of this press can be found here.

|

| The finished press on opening day |

At first this didn't pose a huge issue. While the central screw was exotic, we didn't think it was impossible. The thread is a 2 and 5/16 inch major diameter, 3/16 square thread form, 3 start, 2 inch lead. The most unique part was the very large lead. Originally one of the full time machinists intended to do this thread on our larger ProtoTrak lathe, but we quickly found out between minimum spindle speed and maximum carriage federate, it would be impossible. At this point everyone else in the shop dusted their hands and backed away from the part. I was the only one who was willing to give it a shot it one of our newer machines.

|

| Finished spindle and nut |

|

| Close up of the thread |

|

| Down the barrel of the finished nut |

We had just received delivery of a demo machine, a Tsugami dual spindle y-axis lathe. I ended up coding everything for both the thread and the nut by hand. The external thread was very straightforward to program, but the threading tool gave me a lot of trouble. The idea was to use inserted acme threading tools reground for a square profile but the tools kept cracking off due to how much relief for the large thread lead. After some trial and error (and snapping 12mm cobalt tool blanks in half on the machine during testing) i found a tool geometry that worked. I ran the external thread for both the final part, as well as a shorter, lighter version for me to use as a thread gauge.

|

| Raw stock next to my "thread gauge" |

Lucky for me all of these parts were bespoke, so I only had to make one of each nut and thread and they only had to fit each other. With the external thread complete, I moved on to the internal thread. To this day the brass stock for this nut was the most expensive piece of material I have worked with; 600USD (with half of the cost being in overnight shipping). Unlike the external thread where I could cut the entire thread form with a single tool, the internal thread would require a tool 1/2 inch wide, which would cause chatter no matter how rigid the lathe is. I decided make each internal grove with 5 separate passes with a thin tool on the end of a boring bar. The tool was a smaller version of the external threading tool bolted into the end of a large and stubby boring bar that I also made.

|

| Testing thread contact pattern by smoking the thread |

Again, I manually wrote the program for the internal threads, mostly because I had no idea how I would achieve my desired approach in CAM. This meant for making one set of internal threads, there was 15 independent threading cycles that had to run. Now, because I decided to tweak the nut to fit the screw, I would have to change each of those 15 threading cycles to change the fit. To eliminate this, I parameterized the code. The z thread length and major diameter are both driven by variables at the beginning of the program, so I could easily tweak the program at the machine by changing a single value; not 15 values. I chose to parameterize the z thread length because as I was testing the program, I didn't want to use a ton of material.

|

| Snippet of parameterized code. The numbers in the comments are the z starting locations of each pass |

The strange thread wasn't the only odd feature on the screw. It also included a tapered, rectangular hole. We dont have and EDM capacity at our shop and the team didn't have money to have it sent out. Again, I stepped up the challenge and said I would do it. I pre-drilled to remove most of the material before welding our main band saw's blade into the hole. I first squared out the hole with the band saw, before angling the saw table and band filing a 1 degree taper on all walls. The fact that this technique left a rough finish on the walls was beneficial to the design team, who didn't want perfect faces and surface finishes. On many of the pieces we went back with files and sand paper to roughen up the parts to make them look more handmade.

|

| The 1 degree tapered square hole |

The job was a lot of fun overall and the printing press is now on display at my university. I grew to like that Tsugami lathe but sadly its been moved out to be replaced with some other machines. I also did some miscellaneous parts and welding for the press, one part can be seen below.

A 5 part series of articles about the building of this press can be found here.

|

| Machined oil pan |

Tiger Bot VII Bipedal Robot

This is more of a stub post. Tiger Bot is one of the multiyear senior projects at my university. As I work for the senior design program at my, this was one of the projects I worked on and one of the most complex our shop has managed in the last few years. The task for the team was to design and build a bipedal robotics research platform that mimics human anatomy. This team was only to design the robot, not to program dynamic walk cycles. Below are photos of and models of some of the parts I made for this project. In total I did over 40 parts for this, most of them CAM. All programming was done in Fusion360. Because the number of CNC machined parts on this project was so high, I also worked with team members to teach them how to use the Fusion360 CAM package and run 2-axis CNC mills so they could produce some of the lower complexity parts.

Full documentation of the project can be found here.

Full documentation of the project can be found here.

|

| Robot near final assembly, standing about 1.5 meters |

|

| External hip plates in aluminum, 2 made |

|

| Toe plates in aluminium, 8 made |

|

| Foot strain gauge structures in aluminum, 2 made |

|

| Arm servo replacement face plates, in aluminum, 2 made |

|

| Hip servo replacement face plates in aluminum, 2 made |

|

| Knee harmonic drive mounting bracket in aluminum, mirrored set made |

|

| Ankle servo replacement face plates in aluminum, 2 made |

|

| Heel plate in aluminum, mirrored set made |

Subscribe to:

Comments (Atom)